Body Ailments from Extreme Temperature Swings and a Major Problem Late in Production

Hello everyone!

The transition period from this summer to autumn really took a toll on the body. My body couldn't keep up with the severe temperature swings between day and night, and I was hit squarely with what's known as "Autumn Fatigue" (Akibate). The severe illness led to a terrible situation during a crucial production phase: I ended up bedridden all day for about 20 days...

However, even with a slower pace, I continued working on days I felt better, and I had largely finished all production work. Just as I was about to say, "Time to start selling!" and began the final inspection, a serious problem came to light, which was another disheartening setback.

The Pitfall of "Specifications" Discovered in the Final Inspection

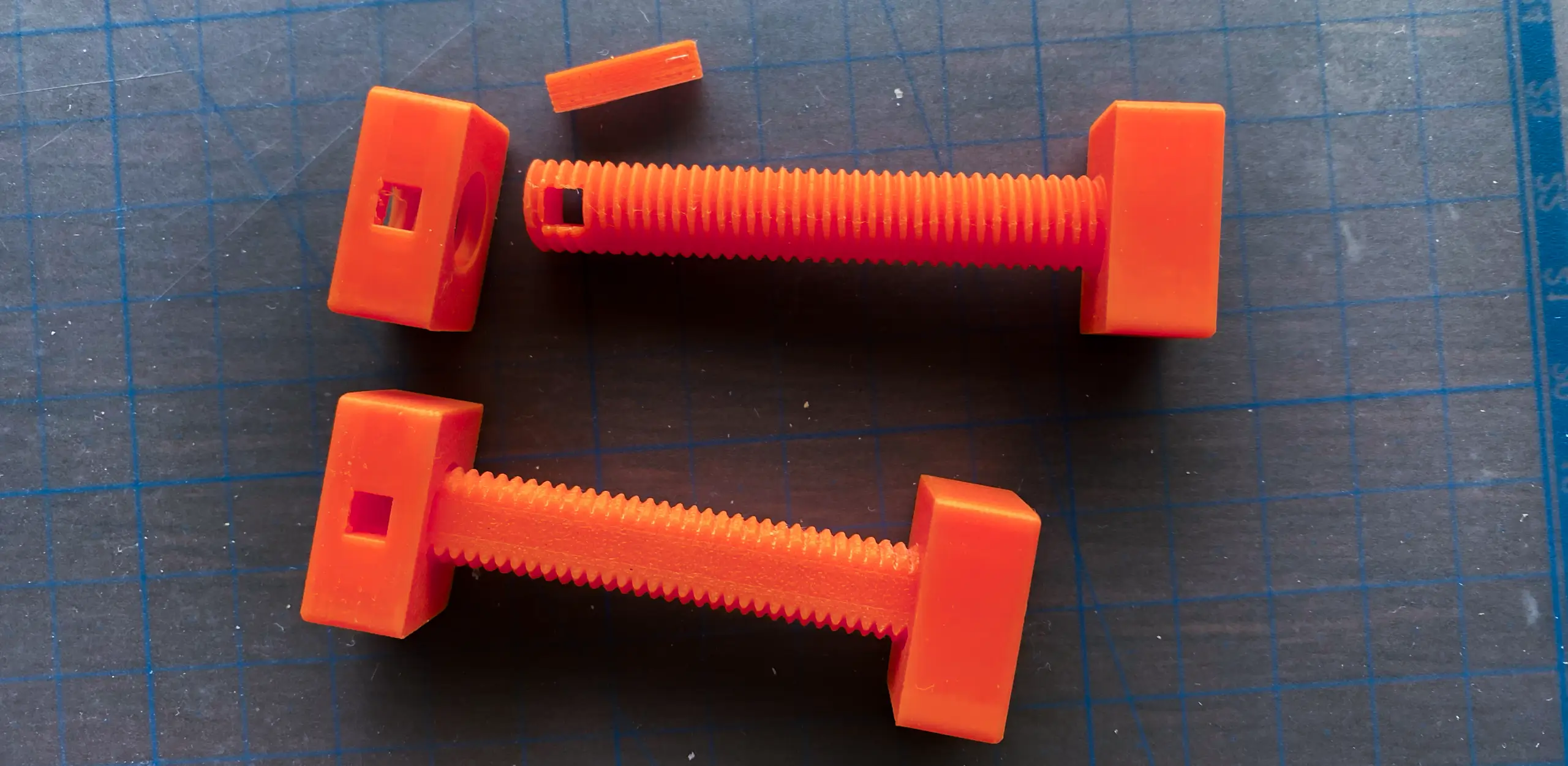

The problem was with the bolts and nuts, which are the core components of the part.

My attempt to balance both strength and design this time unfortunately backfired.

1. Cause of Insufficient Strength:

I adopted a special structure that used a fully threaded bolt and fixed one of the nuts, but this unexpectedly led to insufficient strength. It became more prone to breakage, which was completely counterproductive.

2. Spinning/Poor Tightening:

Furthermore, I found that when trying to tighten the nut firmly, it would spin freely. This was a result of enlarging the nut's hole to make it easier for even women to turn.

We explored various repurposing methods for the bolts and nuts that had already been printed, but ultimately, no suitable solution was found. As a result, a painful loss occurred: about 1000g of printed bolts and nuts that were complete became entirely unusable...

Overcoming the Setback and Moving to More Reliable Specifications!

Honestly, I felt completely devastated, but I couldn't give up here.

I immediately decided to fundamentally review the specifications and redo the design!

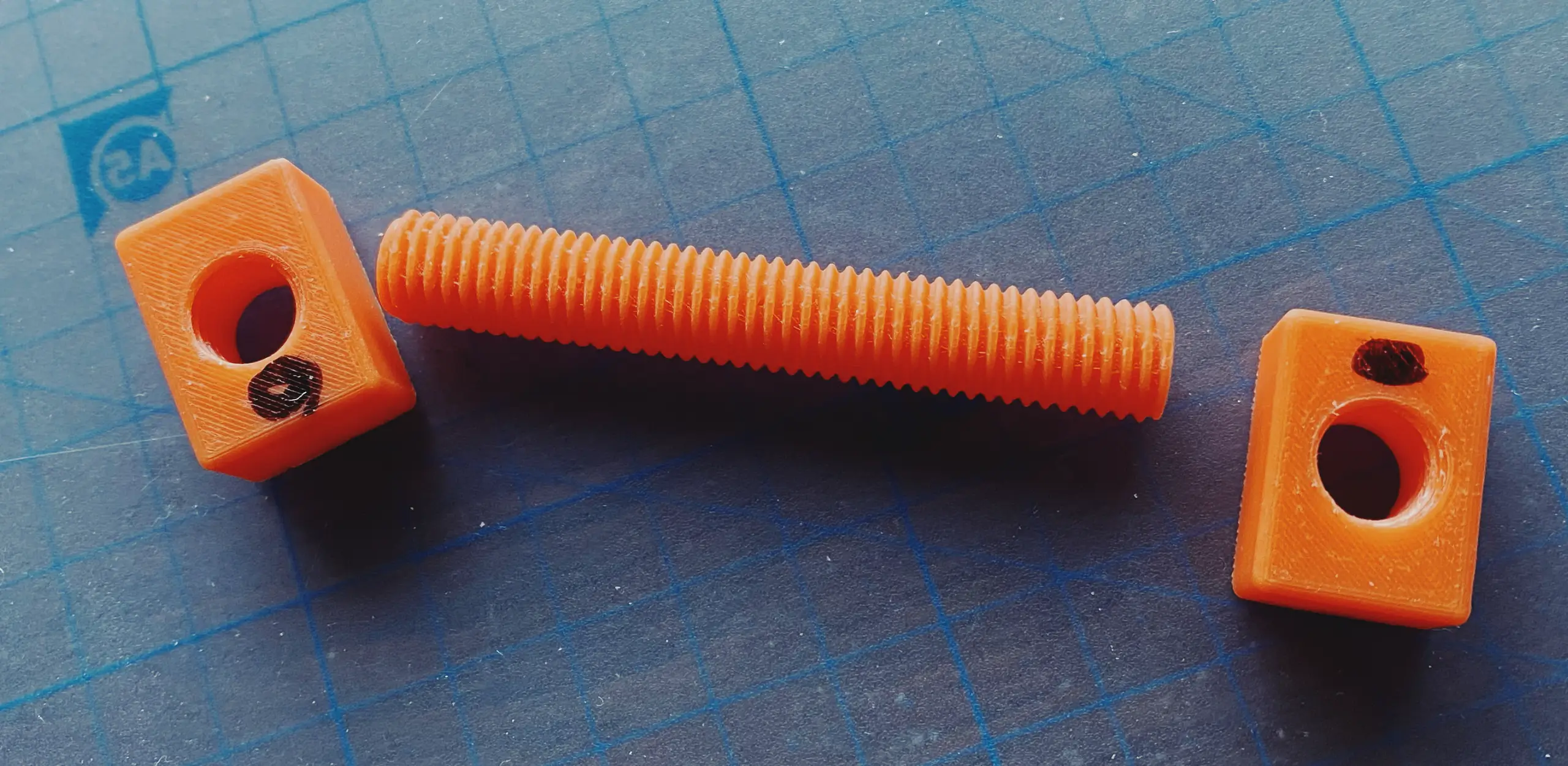

I'm reverting the bolts and nuts to the standard format without trying anything unconventional.

I'm reviewing the combination of structure and material so that the strength won't be compromised even when tightly fastened.

Concurrently, I'm comprehensively overhauling the design of the spacer-related components to maintain overall balance.

As a result, though it took time, I was able to switch to more reliable specifications that compromise neither on quality nor strength!

And finally, the preparation of 30 sets of bolts and nuts is complete! We are now proceeding with the final adjustments under this new specification.

Despite being hit by illness and this unexpected major trouble, I'm confident that the quality of the unseen parts of the product has improved significantly because of it.

The sales launch is just a little while longer! Please look forward to it!