12 circular knitted handles

We are working steadily and steadily to attach the prototype handle to the main body, which was made in the last issue of

”Rethinking handles and new fixtures”. The braiding of the main part is finished, all that remains is to braid the attachment part.

The handles this time were knitted in the round; I had done 4-strand and 6-strand knitting before, but this was my first time doing 12-strand knitting and it was all very confusing.

But once you have the basics down, it's no different to knitting 4 or 6-strand braids.

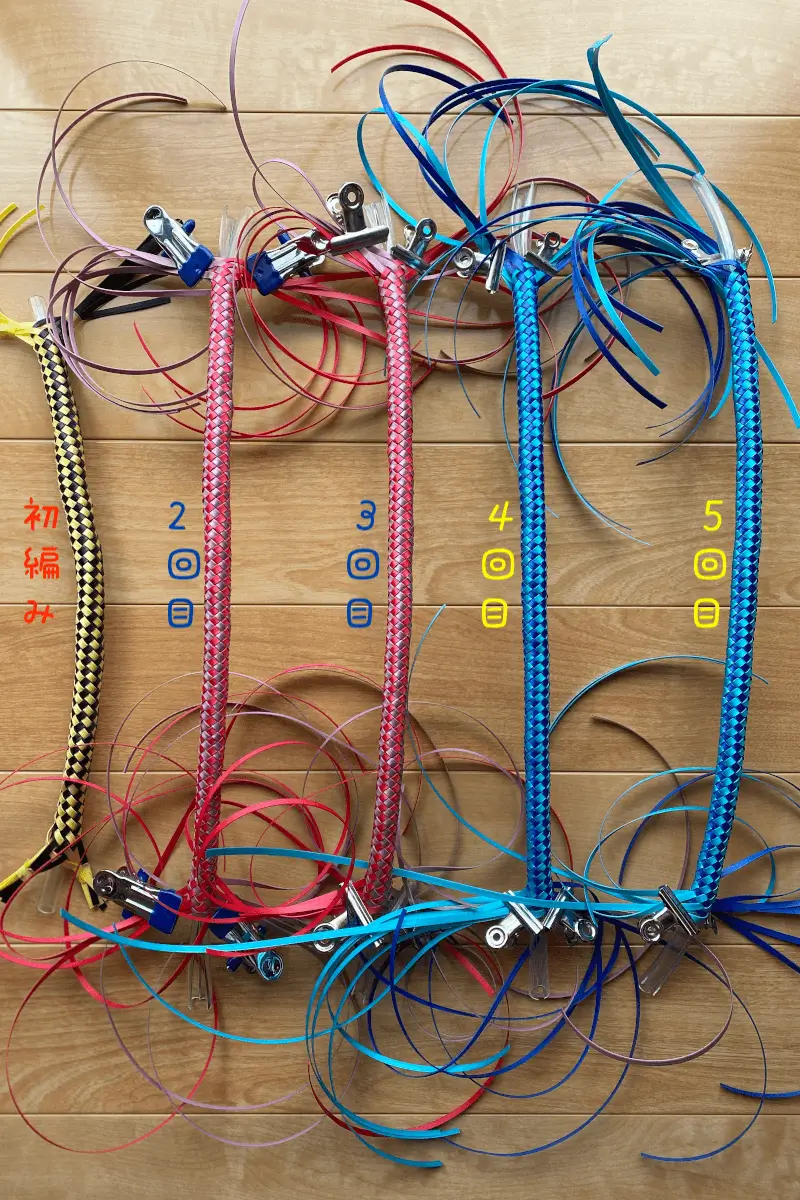

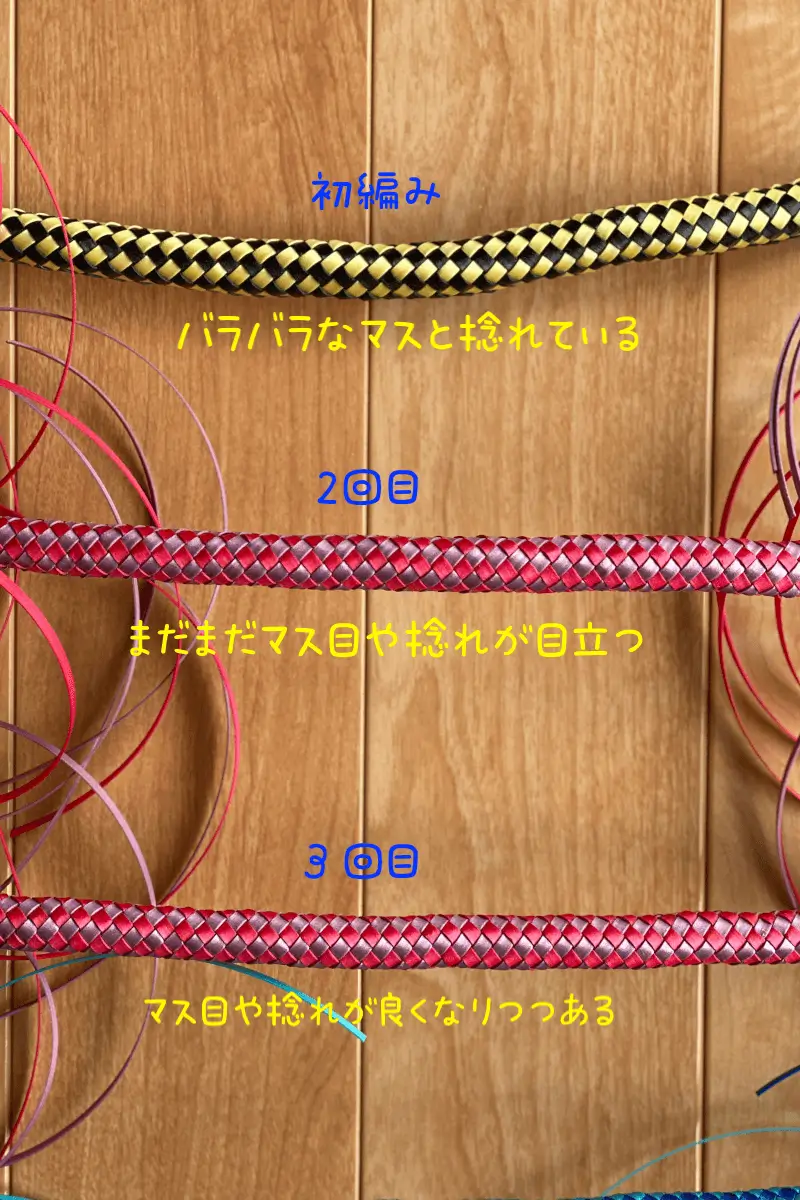

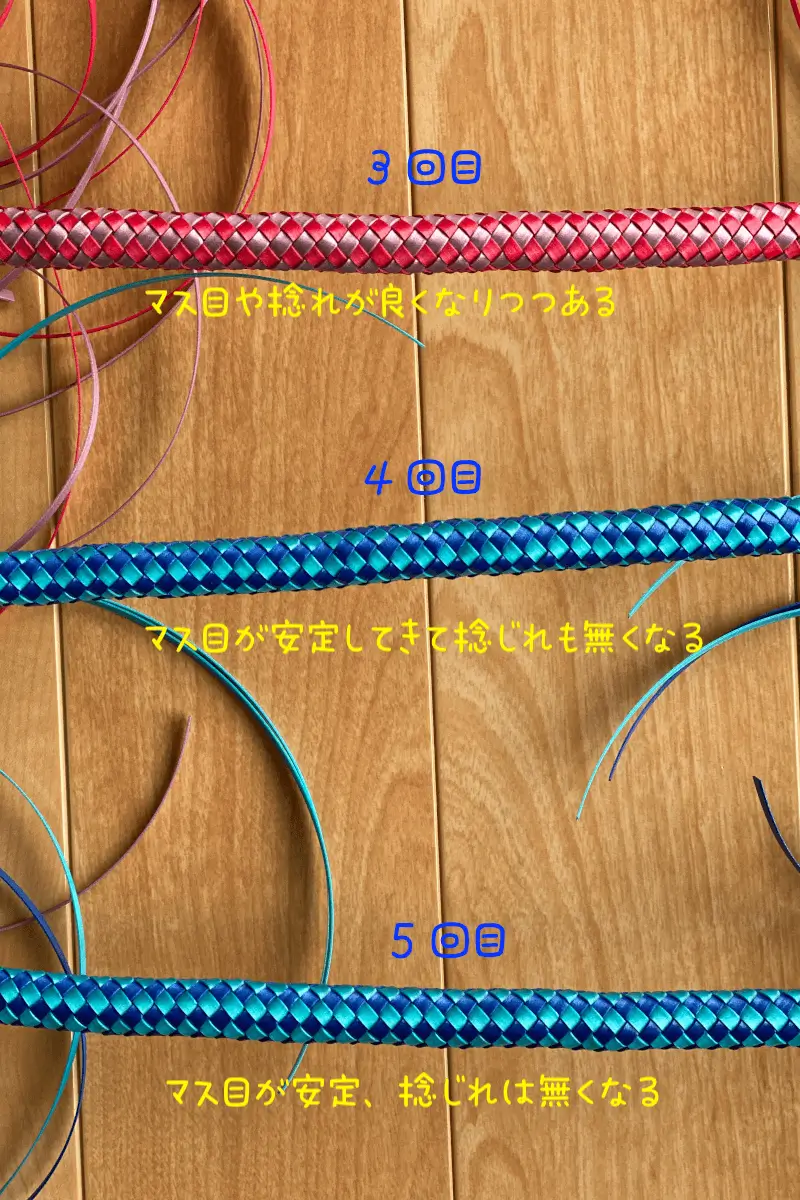

I uploaded the images of the first knitting of the sample and the two sets of 12 round knitting (4 in total) in the order in which they were knitted, because you can still see the difference in knowing and remembering the knitting procedure.

The handles this time were knitted in the round; I had done 4-strand and 6-strand knitting before, but this was my first time doing 12-strand knitting and it was all very confusing.

But once you have the basics down, it's no different to knitting 4 or 6-strand braids.

I uploaded the images of the first knitting of the sample and the two sets of 12 round knitting (4 in total) in the order in which they were knitted, because you can still see the difference in knowing and remembering the knitting procedure.

It may not be helpful because it's only been (braided) five times, but you can see that the distorted squares and twists gradually disappear as the braiding is repeated.

The 12-roll knitting this time was fixed with a jig because there were many knots, but when fixed, if the knitting is done in the correct procedure, it feels tight even if it is not tightened unnecessarily. So I realised that if I wanted to knit neatly in the round, it was important to fix them in place.

They also learn that mass uniformity is a balance between procedure, squeezing, rhythm and force, and that simply tightening with force ruins the material. Well, I think this area is like a craftsman, it's a discipline where you hone your experience until you die.

I was also most worried that the narrow width would make the material fragile and weak, but there is no problem at all.

The way this is going, it's going to have more uses for pulling apart and using it elsewhere...

The 12-roll knitting this time was fixed with a jig because there were many knots, but when fixed, if the knitting is done in the correct procedure, it feels tight even if it is not tightened unnecessarily. So I realised that if I wanted to knit neatly in the round, it was important to fix them in place.

They also learn that mass uniformity is a balance between procedure, squeezing, rhythm and force, and that simply tightening with force ruins the material. Well, I think this area is like a craftsman, it's a discipline where you hone your experience until you die.

I was also most worried that the narrow width would make the material fragile and weak, but there is no problem at all.

The way this is going, it's going to have more uses for pulling apart and using it elsewhere...